Virtual Instrumentation: Revolutionizing Measurement and Control

Virtual instrumentation has revolutionized how we measure and control systems. This technology merges software with traditional hardware instruments to create flexible and cost-effective measurement solutions. Engineers and scientists across various industries now rely on virtual instrumentation for precise data acquisition and control.

What is Virtual Instrumentation?

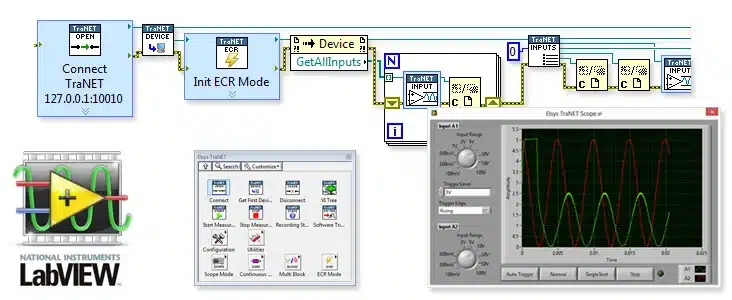

Virtual instrumentation uses software to mimic traditional hardware instruments. This approach allows users to customize measurement and control systems to their specific needs. National Instruments (NI) has been at the forefront of this technology, with its popular LabVIEW software leading the charge.

How Virtual Instrumentation Works

At the heart of virtual instruments lies a powerful combination of hardware and software. The hardware components, such as data acquisition devices, sensors, and signal conditioning equipment, interface with the software. The software processes, analyzes, and visualizes the data. The virtual instruments block diagram represents this interaction, showing how data flows from sensors to the software, enabling real-time monitoring and control.

Advantages of Virtual Instruments

Virtual instruments offer numerous advantages:

- Flexibility: Customize systems to meet specific requirements without the need for multiple hardware devices.

- Cost-Effective: Reduce costs by using software to perform tasks traditionally handled by expensive hardware.

- Scalability: Easily expand or modify systems as needs evolve, saving time and resources.

- Real-Time Analysis: Monitor and analyze data in real-time for faster decision-making.

- Integration: Seamlessly integrate with existing systems and technologies, enhancing overall efficiency.

Key Components of Virtual Instruments

1. Software: Virtual instrumentation software, such as LabVIEW by NI, provides a graphical programming environment. Users can create custom applications for data acquisition, analysis, and control.

2. Hardware: Data acquisition devices, sensors, and signal conditioning equipment interface with the software, capturing and transmitting data for processing.

3. User Interface: The software creates intuitive user interfaces, allowing users to visualize data and control systems easily.

Applications of Virtual Instrumentation

Virtual instrumentation finds applications across various industries:

- Automotive: Monitor and control engine performance, emissions, and other critical parameters.

- Aerospace: Test and evaluate aircraft components, ensuring safety and reliability.

- Manufacturing: Optimize production processes by monitoring machinery and systems in real-time.

- Healthcare: Develop advanced medical devices and diagnostics tools for better patient care.

- Research and Development: Facilitate innovative experiments and prototype testing with precise measurements.

LabVIEW: The Leading Virtual Instruments Software

LabVIEW, developed by National Instruments, is the leading software for virtual instrumentation. It offers a graphical programming environment, enabling users to create custom applications with ease. LabVIEW simplifies the development process, allowing engineers and scientists to focus on innovation rather than coding.

LabVIEW’s virtual instruments block diagram is a powerful tool. It visually represents the flow of data and control signals, making it easy to design and troubleshoot systems. This intuitive interface accelerates development and ensures robust performance.

Choosing the Right Virtual Instruments Products

Selecting the right virtual instrumentation products is crucial for success. Look for reliable suppliers that offer high-quality hardware and software solutions. For a wide range of measuring products, visit. Investing in the right tools ensures accurate measurements, efficient control, and seamless integration with existing systems.

Conclusion

Virtual instrumentation is transforming how industries approach measurement and control. With the flexibility, cost-effectiveness, and scalability of virtual instruments, engineers and scientists can develop customized solutions for their unique needs. National Instruments and its LabVIEW software continue to lead the way, providing robust tools for data acquisition and analysis.

Understanding the advantages of virtual instruments and how it works can help you make informed decisions for your projects. Embrace this technology to unlock new possibilities in your field and achieve greater efficiency and accuracy.

Explore more about virtual instrumentation and find the best products to meet your needs. Stay ahead of the curve with innovative solutions that enhance your measurement and control capabilities.

Related Post

Accurate light measurement is essential for various applications, from ensuring

Analytical balances are essential in laboratories. Their high precision and

Measuring light accurately is essential for various applications. Whether you’re

In our daily lives, light plays a crucial role in

Analytical balances are crucial in scientific research and industrial applications.

Weather stations play a vital role in monitoring and predicting