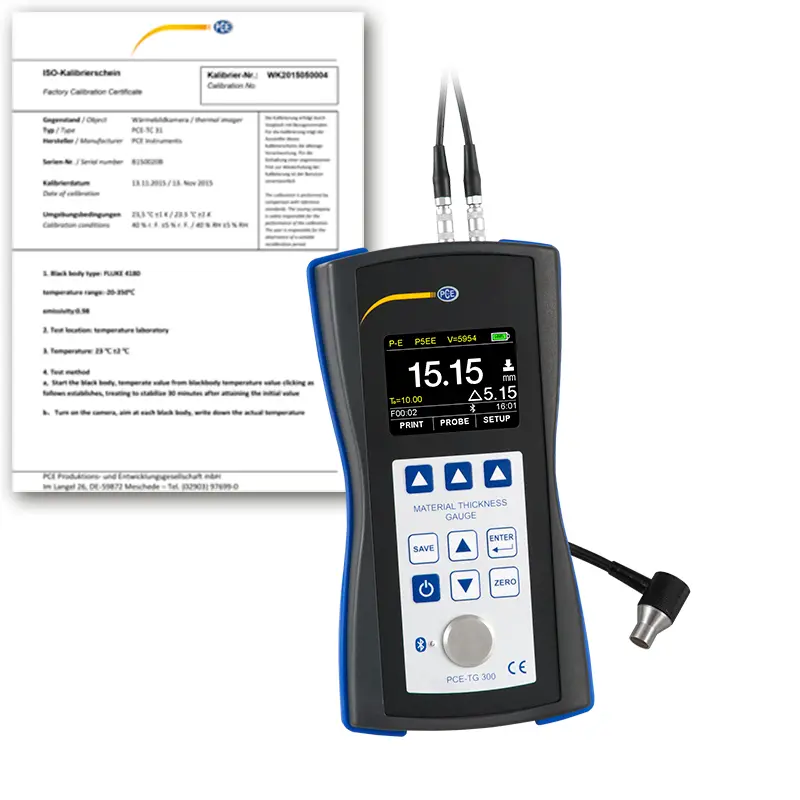

Ultrasonic Tester / Ultrasonic Testing

Ultrasonic Testing (UT) is a non-destructive testing method that uses high-frequency sound waves to detect flaws in materials. Technicians direct ultrasonic pulses into a material and measure the waves’ reflections to identify internal defects. UT is widely used in industries like aerospace, automotive, and manufacturing to ensure structural integrity. This method can detect cracks, voids, and inclusions that other techniques might miss. UT is advantageous due to its precision, depth penetration, and ability to test without causing damage. It also allows for real-time results, making it an essential tool for quality control and safety assurance.

- Measuring range: 0.65 … 200 mm / 0.025 … 7.87″ (steel)

- Measuring range: 3.0 … 300.0 mm / 0.118 … 11.81″ (steel)

- Measuring range: 1 … 600 mm / 0.039 … 23.62″ (steel)

- Diameter: 12mm / 0.47″

- Minimum diameter of pipes: 30 mm / 1.18″

- Frequency: 5MHz

- Measuring range: P-E: 2 … 600 mm / 0.07 … 23.62″, E-E: 2.5 … 100 mm / 0.09 …3.93″

- Diameter: 10mm / 0.39″

- Minimum diameter of pipes: 20 x 3 mm / 0.787 … 0.118″

-

Test range: 0 … 10000 mm

-

Pulse shift: -20 … +3400 µs

-

Single or dual probe measurement

-

AVG and DAC evaluation methods

-

Speed of sound 1000 … 15000 m/s